Innovative, impactful, novel. These are the pillars around which Alice Casagrande Cesconetto, Claire Mundy, Emily Bliven, and Georgia Gryzbowski built their latest project, an improved harness for infants with developmental dysplasia of the hip (DDH).

These SBME students had the opportunity to apply their engineering knowledge and skills in a clinical setting in the Engineers in Scrubs (EiS) program, which is celebrating its tenth cohort this year. Cesconetto, Mundy, Bliven, and Gryzbowski were driven to enhance the existing standard of treatment for DDH—the Pavlik harness—because of the potential impact it could have on infant health, as 1-3% of infants are diagnosed with DDH each year. They were drawn to this project because it was the perfect synthesis of human-centric design and mechanical engineering with the potential to make an immediate difference in people’s lives.

Though the Pavlik harness is an overall effective solution for DDH, treatment usually requires that the harness is worn constantly for weeks at a time, and a frequent complaint from parents and caretakers of infants with DDH is that the harness can cause skin irritation. Working closely with Dr. Kishore Mulpuri and his team at BC Children’s Hospital as part of the clinical component of EiS, the four also found that caretakers found the Pavlik harness confusing to use and difficult to keep clean, as it can’t go into a bath along with the child.

And so the student team embarked on process to create a harness that addressed the drawbacks of the Pavlik system while maintaining the level of treatment efficacy.

Dr. Mulpuri facilitated in-person meetings and clinic shadowing sessions between the engineering students and families of infants with DDH. For Cesconetto, Mundy, Bliven, and Gryzbowski, this partnership was a valuable experience and a crucial step in producing a prototype that met their design requirements and had potential to be applied in real life.

“Dr. Kishore Mulpuri is an open-minded and creative partner on this project,” the team agrees, “and he shares our passion for treating and reducing the incidence of DDH. Our collaboration was a great balance of Dr. Mulpuri providing his clinical expertise when we needed it and then allowing us engineers to ‘do our thing’ and present iterative designs. It’s hands-on engineering meets medicine.”

All four members were initially attracted to the EiS program because of this hands-on opportunity to combine engineering and healthcare applications with the potential to see the fruits of their work in action.

The program gave us the opportunity to collaborate with clinicians to solve real-world medical problems, and we knew that we would end the course with something tangible.

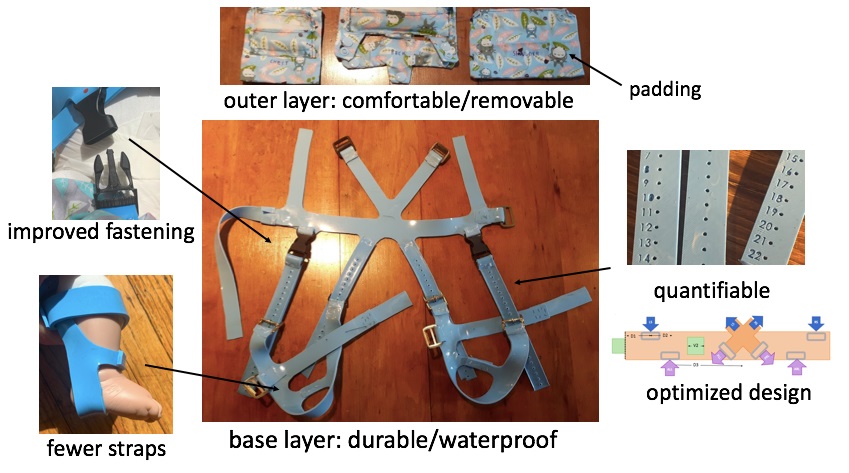

The team’s harness design consists of two layers: a fully submersible and quick-drying inner layer that provides the same degree of support as the current standard of care and a washable outer layer that offers extra padding and comfort, and is easy to take on and off.

With the COVID-19 pandemic entering the picture at a key stage of their prototyping process, these SBME students were pushed to adapt on the fly. Even after moving their meetings online and increasing sanitizing measures, the four engineers were still forced to reluctantly step back from working in a clinical setting and presenting their harness to clinicians. It was simply too difficult to demonstrate their prototype’s features through videos alone. Instead, they are now using this time to refocus on improving the current prototype and coordinating manufacturing efforts. Once COVID-19 no longer poses a public health risk and there is less uncertainty around returning to work in person, the SBME engineering team plans on organizing a clinical trial to compare their fine-tuned prototype with the existing standard.

With the COVID-19 pandemic entering the picture at a key stage of their prototyping process, these SBME students were pushed to adapt on the fly. Even after moving their meetings online and increasing sanitizing measures, the four engineers were still forced to reluctantly step back from working in a clinical setting and presenting their harness to clinicians. It was simply too difficult to demonstrate their prototype’s features through videos alone. Instead, they are now using this time to refocus on improving the current prototype and coordinating manufacturing efforts. Once COVID-19 no longer poses a public health risk and there is less uncertainty around returning to work in person, the SBME engineering team plans on organizing a clinical trial to compare their fine-tuned prototype with the existing standard.

“Our long-term hope is that having an easier-to-use option that is better liked by users will result in improved treatment compliance and a better experience overall.”

(All images provided courtesy of the team. To request permission to use these images, please contact SBME Communications)

This story is part of the SBME’s Pipeline to Innovation series. Follow along as we Discover, Invent, and Translate for the future.