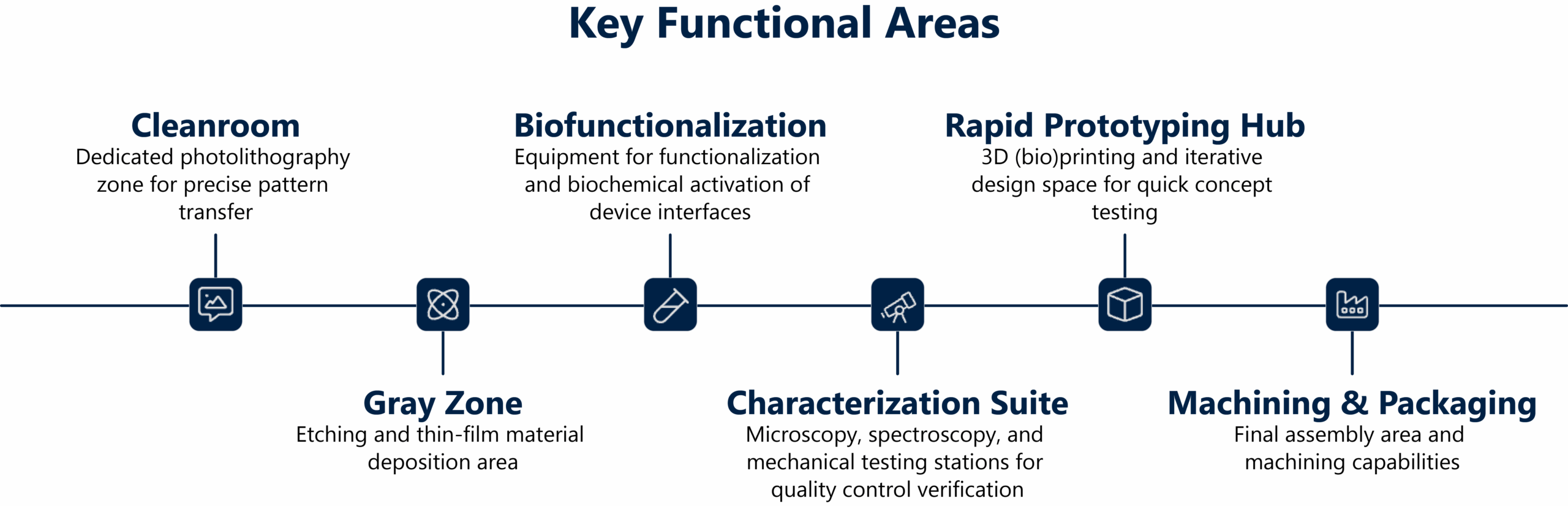

The Conconi Family BioDevice Foundry at UBC is a shared use core facility bridging microfabrication with biotechnological and biomedical applications. It co-localizes a traditional cleanroom environment with bio-functionalization, characterization, rapid prototyping and machining for design, fabrication and characterization of microscale biodevices that support cutting-edge life sciences research. Access to the foundry and to all instruments is available to qualified users from UBC, other education institutions, or industry, and we welcome researchers from all disciplines wishing to explore uses of the facility.

Over 50 pieces of equipment in a 5,000+ square feet laboratory space

Fully equipped 4” (100 mm) and 6” (150mm) processing capabilities. State-of-the-art microfabrication and nanofabrication equipment

Comprehensive capabilities for lithography, thin-film deposition, plasma etching, and wet chemical processing

Advanced microscopy, spectroscopy, and rheological analysis

Biochemistry lab for active bio-activation of device surface in applications of MEMS, microfluidics and biodevices

Rapid prototyping and precision machining for device packaging

Objectives

- Bridge micro/nanofabrication and biotechnology

- Advance biodevices and life sciences research

- Hands-on training in cutting-edge micro/nanofabrication and biodevice technology

- Support academic and industry development through proof of concept, process development and characterization

- Prototyping, low manufacturing & commercialization support for industry & startups

Get access – today!

Conconi Family BioDevice Foundry

SBME, UBC

Directory

Fabrication & Prototyping

Biofunctionalization

Characterization

Resources & Services